By Caroline Newman

Photos by James and Rachel Culver

Daniel Meadows never wanted his knives to look generic. He wanted them to be distinctive, designed with memorable flair and with extraordinary function. He custom-designs each one and tests it ruthlessly, not content until the knife can slice a paper towel cleanly in one stroke or dice a grape without any slipping or sliding.

“That is when I know it’s ready to go,” says Daniel, who runs Meadows Knives out of his garage workshop in Shelby County. “There are so many different things to think about – the weight, the balance, how the knife is centered when I hold it. I obsess about all of those things.”

That attention to detail has brought Meadows Knives to the attention of chefs in Alabama and beyond. Meadows, who started the business in 2018, has a roster of local chefs among his clients, including chef husband-and-wife duo Tyler and Jennifer Lyne. Tyler is an Iron Chef winner and has worked with 1856 in Auburn and the soon-to-come Frenchie’s Café in Birmingham. Jennifer is a classically trained pastry chef and, together with Tyler, hosts intimate Tasting TBL dinners in the couple’s home.

Also among Daniel’s clients are Jeffrey Compton, who is the executive chef of The Battery in Homewood and recent winner of the Alabama Seafood Cook-Off; and several chefs at Acre, a farm-to-table restaurant now renowned as a culinary destination in Auburn.

Daniel himself is an Auburn graduate, earning a degree in industrial design. Even as he went on to a career in marketing, he kept that interest in design alive and turned his attention to the culinary world, which had always intrigued him.

“I have always had a passion for the cooking industry and had a lot of friends who are chefs,” he says. “I did not necessarily want to be a chef, but I knew I could put my skills to use, building something that my friends could use.”

Daniel started making knives for fun and taught himself various techniques, studying videos on YouTube. He gave a few knives to his chef friends to test out and, about a year later, put his first knife up for sale. Now, he has more than 3,000 followers on Instagram, where chefs and amateurs alike are drawn to his knives’ unique designs. He makes mostly chef knives, along with some long, narrow sushi knives and a few smaller oyster knives that clients have asked for.

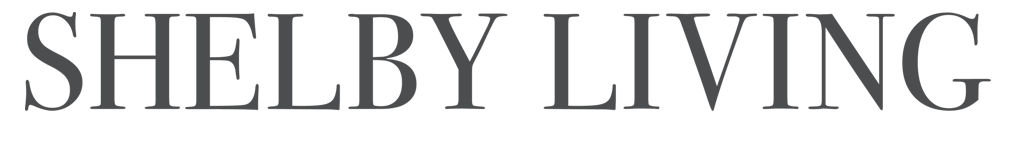

Among the knives’ features are the resin handles, which Daniel hand-dyes and carves. His knives also have a distinctive black edge that comes from the San Mai technique that he uses to forge the blade, a Japanese technique that combines three layers of steel: two stainless steel pieces and one carbon steel piece. The carbon steel is sandwiched and hammered between the stainless steel. Daniel then etches the carbon steel, creating the curled black edges seen along his knives.

“I didn’t want to create something cookie cutter,” he says, noting that anyone expecting a plain, black-handled knife should look elsewhere. “I want each knife to have a personal feel and a bright, colorful design. I talk to people about what colors they like, what type of steel they want. I love talking through those things, and I have made a lot of good friends through those conversations.”

Each custom knife can take upwards of 32 hours to make. Daniel makes the blade first, hammering out and shaping large bolts of steel. The steel must be hardened in a 1,400-degree oven and then dipped in a vat of cool oil to set before baking for four hours to get to the right level of strength. Then, he dyes and carves the resin handle, often going through several iterations to get to the handle he feels best fits each knife.

Daniel does all of this in the garage workshop attached to the home he shares with his wife, Ashley. It is a three-car garage that, he jokes, never has a car in it. Instead, it is filled with the specialty ovens, anvils and other equipment he needs.

He spends most nights and weekends in that garage after wrapping up his day job, working remotely as a creative director for a North Carolina-based marketing firm.

“Meadows Knives takes up pretty much every ounce of my free time,” Daniel says. “We really started growing our sales over the past year. I still make one knife at a time, to get the detail right, so it can get time-consuming.”

It’s a lot of work, and it’s “even harder than it looks,” but he still loves it.

“I have a really strong passion for this industry, and I have met so many awesome people,” he says. “I have really enjoyed it, and I am excited to keep growing.”

Meadows Knives can do custom orders for chefs or other clients interested in high-quality culinary knives. Pricing is not fixed. It is based on each client’s custom order.

To learn more about Meadows Knives, follow Daniel’s Instagram page @meadowsknives, follow Meadows Knives on Facebook or visit meadowsknives.bigcartel.com.